Question 1

Please expand on your experience with the different structural options for office and Residential as described in the concept package.

Structural Steel

The concept and 50% SD drawings call for structural steel framing in the commercial tower starting from the amenities floor on L12 to the roof. The framing generally comprises steel columns at approx. 30’ in the NE (plan EW) direction by 43’ to 46’ in the NW direction (plan NS) connected by W18, W21, and W24 beams and girders with W18 beams for the spandrels. Intermediate beams split the column spans in the short direction for a maximum of slab spans of 15’. Moment connections are limited to supporting cantilevered slab overhangs with approximately four per floor. However, as noted in the sloping column considerations, significant forces may result in the floor plane due to the building lean and sloping columns. In these areas, larger moment connections and connecting girders may be required as the design develops and/or for means and methods during erection. Additionally, larger spandrels or reinforcing elements may be needed to support the curtain wall panels on the underside of the inclined tower portion.

Floor Framing Considerations: Upper Portion of the Commercial Tower

The structural steel beams act compositely with 6.5” slab-on-deck. The metal decking is composite with the slab and comprised of 3.5” LW Concrete atop a 3” troughed metal deck. With 3.5” LW concrete above the deck trough, the decking will not need additional fireproofing.

With the typical metal deck span being 15’ or less, utilizing a 16- or 18-gauge metal deck in two or three span configurations will allow for casting without the need for supplemental shoring of the decking. Single spans will require shoring during construction. Refer to extract in the following figure.

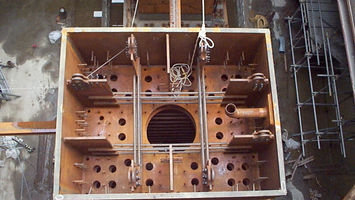

Figure 1 Excerpts from 50% SD Drawings CS0.00 (Steel Columns in Red) & CS1.21 (Steel Framing Plan)

Figure 2 Typical Composite Metal Decking Extract

Structural Steel and Composite Tower Examples

Turner is well versed in structural steel towers and various forms of composite structural steel and concrete structures, with similar elements to the Greyhound Commercial Tower. The following include several domestic and international examples.

Hearst Tower, New York

Comprised of inclined columns in a diagrid formation, the 46-story, the Hearst Tower with 858,000 SF of commercial office space was built within and above the original six-story Hearst office building. The 1928 landmark façade was restored and integrated with the tower. The structural frame, standing 598 feet tall, is enclosed with a panelized glass curtain wall system and stainless-steel diagrid cladding. The diagrid (triangulated) steel frame uses 21% less steel than a traditionally framed building, saving 2,000 tons of steel.

Figure 3 Hearst Tower Under Construction

The Spiral, New York

The Spiral is a 65-story, 1,005-ft. office tower was sustainably constructed in the Hudson Yards district of Manhattan’s Midtown West. The tower comprises 2.85 million square feet along with a concrete core with structural steel columns and floor framing along with slab on metal deck. This tower had the concrete core follow the structural steel floor framing. As the tower climbed, the core was braced with structural steel bracing to laterally brace the floor and the core concreting followed behind.

Figure 4 Spiral Tower Under Construction

Taipei 101, Taipei

The world’s tall building when completed, the 508-meter Taipei 101 comprised of composite structural steel and columns and concrete core with 100,000 tonnes of structural steel.

Structural steel features of interest:

-

Built-up Concrete Filled Tubes (CFTs): High Strength / High Performance

-

SM570M High Strength and High Ductility Steel Plates: 410 MPa to 510 MPa (60 ksi to 74 ksi)

-

High ductility :

-

Yield ratio ≤ 80% For girders & braces (t > 40 mm )

-

≤ 85% For girders & braces (t ≤ 40 mm ), columns

-

-

High weldability : Ceq ≤ 0.44 % ( t < 40 mm ) ≤ 0.47 % ( t ≥ 40 mm )

-

Through-thickness ductility

-

High Ductility Beam-Column Connection

-

Reduced Beam Sections (Dog-Bones) Used for tower columns, girders & braces

Figure 5 Taipei 101 Steel Structure

Merdeka 118, Kuala Lumpur

Merdeka 118 is a 118-storey, 680-metre (2,070-foot) mega tall skyscraper and is currently the 2nd tallest building in the world. The tower structure comprises a steel perimeter braced frame and structural steel outriggers and belt trusses with composite structural steel and metal deck floor framing and concrete core. The heaviest crane pick on the project was an outrigger node at 44.3 Tonnes (49 Tons). These elements were originally planned as cast nodes but were later modified to a weldment.

Figure 6 Merdeka 118 Steel Structure and Outriggers

BBVA, Mexico City

The 51-story, 235-meter (771-ft.) BBVA office tower is comprised of a concrete core with a structural steel eccentrically perimeter braced frame (ECB) with composite steel floor framing. This 183,000 square meter (2‑million sq, ft.) tower was the first use of ArcelorMittal’s 70ksi Histar structural steel material for ECB Frames, which reduce the need to preheat the field welded sections. The tower has weathered tower several earthquakes during construction and following completion without issue.

Figure 7 BBVA Tower Steel Structure

VietinBank Tower, Hanoi

This 360-meter (1,180 ft.), 68-story, tower comprising over 30,000 tonnes of structural steel in the form of braced interior frames with composite mega columns. The tower mega-braces act compositely with the building core located at each apex of the triangular frame.

Structural steel notes of interest:

-

Composite metal decking with proper sequencing and minimal rebar

-

Using the Tatekata system to install the columns.

Figure 8 VietinBank Tower Steel Construction

Bitexco Financial Tower, HCMC

The 68-story, 262-meter (861-ft.) Bitexco Financial Tower is an example of a concrete structure acting compositely structural steel outriggers and a structural steel helipad; the outriggers were re-designed from PT concrete to composite structural steel in a joint effort from Turner, Hyundai E&C, and the international structural engineer, LERA.

Notable structural steel features include:

-

Structural Steel: Helipad at Floor 50, Outriggers, and Podium

-

Outriggers are comprised of composite braced frames.

-

Long-span transfer trusses (also redesigned based on Turner input)

-

Tallest building in Vietnam when completed

Key Stats:

-

Largest Member – Built-up shape, 2.6m deep, 125mm thick flanges

-

Heaviest Member – 23 T (w/o connection plates) (This determined luffing crane capacity)

-

Fabricated in Korea and Vietnam

-

Pre-assembled at factory prior to beginning site erection.

-

Bolts – Approximately 4000 (using DTIs)

Figure 9 Bitexco Steel Structure

Statue of Unity, Gujarat

Turner delivered the Statue of Unity, the world’s tallest statue at 182-meters and is a model of Sardar Vallabhbhai Patel.

The composite structure is comprised of a structural steel braced frame supported from a composite concrete core to form the statue’s unique shape. Unlike most statues, the Statue of Unity narrows at the base to expose the ankles, becoming the critical attribute to the lateral stability; as opposed to most statues that have in increased bases (normally hidden under flowing robes) to resist overturning moments.

Figure 10 Status of Unity Steel Structure

JW Marriot, Hanoi

The JW Marriott Hanoi is an example of structural steel supported on a concrete structure. Although low-rise, both structures lean and cantilever of plane significantly. Of the cantilevered overhangs shown below, one suspends five floors of concrete framed floor structure and the other is a 50 meters (164-ft.) span supporting the hotel’s swimming pool.

Figure 11 JW Marriott Hanoi Steel Structure and Steel Overhang